- Products

No.123C07

May 2, 2022

Launch of 3D Decorative Biomass Film for Automotive Interiors.

Contributing to Sustainable Car Manufacturing with Paint-Alternative Biomass Films.

Aica Kogyo Co., Ltd. (President: Kenji Ebihara, Headquarters: Nakamura-ku, Nagoya, Aichi Prefecture) has developed a UV-curable 3D decorative hard-coated film using biomass materials for automotive interiors. Full-scale sample work began in April, with the product launching in June.

-

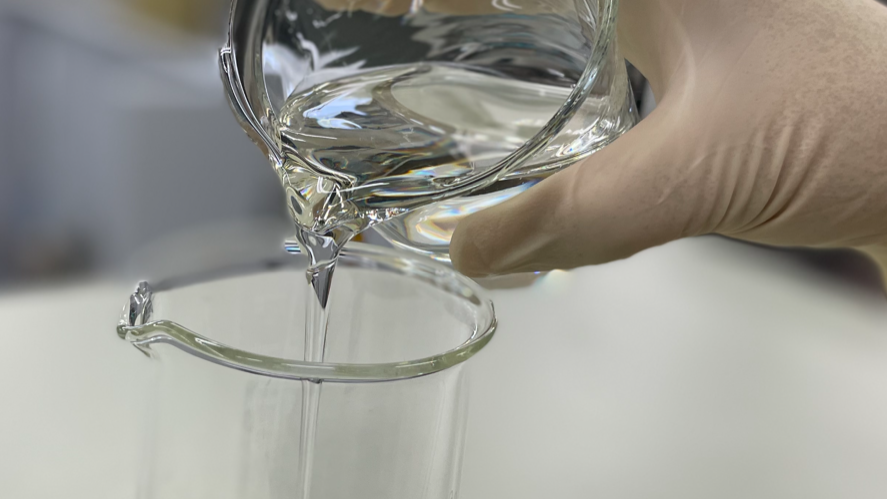

Biomass material used for hard coatings

-

Example of 3D decoration application (automobile interior, image)

Development Background

As the SDGs (Sustainable Development Goals) gain traction, there has been increasing demand from customers for environmentally friendly products. Aica Kogyo, which deals with resin products, is transitioning from fossil-derived materials to sustainable resources and has been working on developing products using biomass materials.

In September 2021, the company launched UV-curable hard-coat agents and films that partially use biomass materials derived from plants such as corn and soybeans. These products have been widely adopted in displays and electronic device housings. Now, they have developed a UV-curable hard-coat resin using biomass materials for more complex shapes, specifically for 3D decorative applications. From April, full-scale sample work began for 3D decorative hard-coated films using this resin, primarily for interior display panels and heater control units in automotive interiors, with a scheduled release in June.

Recently, there has been an increasing demand in the automotive industry for environmentally friendly materials. Decorative films are gaining attention as alternative materials to paint, which raises concerns over VOC (Volatile Organic Compounds) emissions and the generation of large amounts of wastewater. Going forward, Aica Kogyo plans to expand biomass technology to 3D decorative films for automotive exteriors, contributing to the achievement of SDGs and the realization of a sustainable society.

Note 1: Refers to a molding method where a decorative film is applied to an already-formed object (such as a panel), requiring the film to have high elongation.

Note 2: Abbreviation for Volatile Organic Compounds, which include toluene, xylene, formaldehyde, and others, known to cause air pollution and health issues.

Reference: Related News

Product Features

- Achieves 30-40% biomass content, making it an environmentally friendly product.

- Maintains the same workability and performance as conventional products, despite being eco-friendly.

- During high-temperature thermoforming, the film exhibits flexibility and high elongation, allowing it to adapt to complex shapes. After forming, it exhibits high abrasion resistance, chemical resistance, and pencil hardness at room temperature.

- 3D decorative hard-coated films can be integrated with automotive interior molded products.

- Pre-cure type films do not require UV exposure in later processes, eliminating the need for additional equipment investment.

- Compatible with acquiring the biomass mark upon customer request.

Note 3: This figure applies to the 3D decorative hard-coated film.

Note 4: A pre-cure method where the film is UV-cured before thermoforming, eliminating the need for UV curing afterward. In contrast, the after-cure type, which involves UV curing after the film is molded, requires a significant investment in equipment, including multiple large UV lamps depending on the molded product.

Note 5: The Biomass Mark is a certification for environmental products that utilize biological resources and comply with relevant laws, standards, and specifications in Japan. This mark is operated by the Japan Organics Recycling Association (JRA). It indicates the biomass content, known as “biomass degree,” which ranges from a minimum of 10% to a maximum of 100% in increments of 5%. Since the mark is assigned to individual products, this customized product does not bear the mark, but we can accommodate users' requests.

Product Overview

| Product Name | Biomass 3D Decorative Hard-Coated Film "Lumiart HC Series" |

| Application | Decorative films for automotive interior parts such as display panels and heater control units |

Sales Start Date

June 2022 (Full-scale sample work started in April 2022)

Annual Sales Target

300 million yen

Note: The information in this news release (such as product pricing, specifications, service details, release dates, URLs, etc.) is current as of the announcement date. Please be aware that these details may change without notice and could differ at the time you view them. For the latest information, please contact us here.

-

Search by year