- HOME

- Product Information

- Specially & Perfomance Materials

- Polymer beads

- STAPHYLOID Mulitilayer Construction polymer beads

Polymer beads

“STAPHYLOID” are multilayer construction polymer beads synthesized core-shell emulsion polymerization. These have the following features.

Product development by Use

Modifier for the coating of metals

- This is a fine particle characterized by a multiple-layer structure with a core part (with a soft composition) and a shell part (with a hard composition). By adding it to resin used for the coating of metals and dispersing it, the rubber-like polymer of the core part will manifest effects which serve to alleviate internal stress. This makes it possible to improve adhesiveness, adhesion and acquire shock resistance and workability in bending process.

- It can be dispersed easily on various resins used for the coating of metals.

- Dispersion to the resin can be improved by modifying the shell part by the hydroxy group and the carboxyl group.

Impact Modifier

- This is a fine particle characterized by a multiple-layer structure with a core part (with a soft composition) and a shell part (with a hard composition). By adding it to engineering plastic and dispersing it, the rubber-like polymer of the core part will manifest effects which serve to alleviate internal stress and thereby increase shock resistance.

- There are no impurities such as emulsifiers, which means superior weather-resistance.

- We can also prepare grades which have extremely small amounts of ionic impurities for items which are geared toward electronic material.

Unsaturated polyester resin low constrictive agent

- When used as a low constrictive agent of unsaturated polyester, STAPHYLOID improves moldadility by reducing binding during the molding process.

- With excellent transparency, coloring properties (produces uniform color disribution) and boiling resistance, it gives molded material a smooth, flat surface.

Technical Information

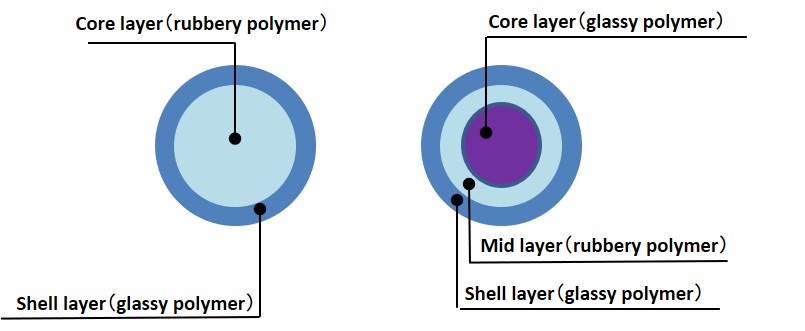

The STAPHYLOID Series basically consists of spherical, fine particles with core-shell structures wherein there is a core layer made of a rubber-like polymer (as shown in the figure) that is coated with a shell layer consisting of a glass-like polymer. A multi-layer structure like that shown in the figure below is also used depending on the application. The particle size can be controlled within a scope of 0.1 to 0.5 μm. The product consists of secondary particles wherein large numbers of these primary particles assemble together.

| Core | This is made from a rubber-like polymer that is characterized by a low Tg level and comprised of homopolymers or copolymers consisting of acrylic monomers. It functions as a point where internal stress concentrates to improve impact strength and alleviate internal stress. |

|---|---|

| Shell |

This is made from polymer having a high Tg level.

|